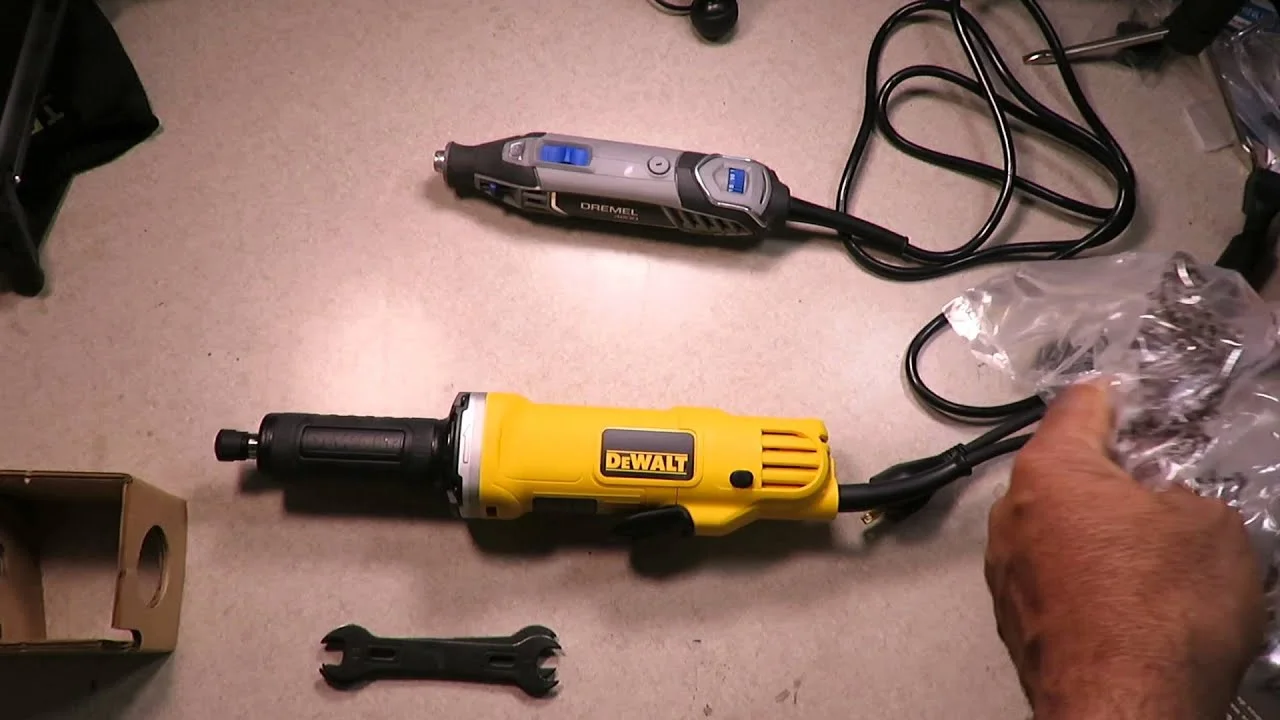

Die grinder vs Dremel – Which Rotary tool Is Better?

Die grinders and Dremels are both rotary tools. These tools are very popular with homeowners and professionals working on different commercial projects.

Die grinders are ideal when high power, speed, and torque is need for cutting, grinding, and removing metal, masonry, and building materials.

Dremels excel at lighter duty jobs requiring precision control – small part crafting, cleaning, polishing, engraving, and detail work.

You can use both tools in projects that involve polishing, grinding, sanding, sharpening and carving.

However, the two tools are very similar and this confuses many buyers on which to buy. For you to decide on which is the better tool between Dremel and die grinder, we are going to look at the main features of the two. This will give you a true picture on which tool can serve your needs the best.

Die grinder vs Dremel Comparison

| Comparison Factors | Dremel Rotary Tool | Die Grinder |

|---|---|---|

| Brand vs. Tool | Dremel is a brand | Die grinder is a type of tool |

| Power Source | Electric | Pneumatic (air compressor) or electric |

| Size | Smaller | Larger |

| Speed | Faster (higher RPM) | Slower (lower RPM) |

| Power/Torque | Less powerful | More powerful |

| Versatility | Versatile, but limited by size | Highly versatile |

| Tool Bit Size | Up to 1/8″ (3mm) | Accepts both small and large bits |

| Variable Speed | Yes | Only in electric and cordless versions |

| Overheating | Prone to overheating | Less prone to overheating due to faster completion |

| Price | Expensive | Inexpensive (pneumatic) or variable (electric/cordless) |

What are rotary tools?

A rotary tool is a handheld power tool that operates by spinning a small cutting, grinding, or polishing attachment. Rotary tools typically have a variable speed control and interchangeable attachments that can be easily swapped out for different tasks. They are compact and lightweight, making them easy to maneuver and control.

Rotary tools are commonly used in various industries such as woodworking, metalworking, jewelry making, and crafting.

American inventor Albert J. Dremel invented the high-speed rotary tool in 1934.

wikipedia

The Basic Components

- Motor – Provides the power to spin the bit at high speeds (typically 5,000 – 35,000 rpm). Can be electric corded or cordless battery-powered.

- Collet – Holds and locks interchangeable accessory bits and attachments. Usually has a chuck or tightening nut.

- Bit/Accessory – The cutting, grinding, sanding, or polishing attachment that spins at the end of the tool. Many types available.

- Body – Houses the motor and has an ergonomic grip for handling. Made of durable plastic or metal.

- Speed Control – Allows user to adjust/vary the rotational speed as needed for different materials/tasks.

- Power Switch – Turns tool on/off. Can have variable triggers or preset speed locks. Safety switches are common.

- Cord/Battery – Provides electrical power. Corded tools plug into outlet. Cordless use rechargeable battery packs.

- Wheel Guard – A safety cover around spinning bits for protection and preventing contact.

- Stand/Flex Shaft – Optional attachments to stabilize tool or reach tight areas.

What is die grinder

A die grinder is a special high-powered rotary tool made specifically for grinding, cutting, and deburring metal.

You can find them in fast electric motor or air-power motor which could spins at 25,000 – 40,000 rpm which is faster than regular rotary common tools.

They are designed to handle hard materials like grind metal and steel.

They come in the form of both cordless die grinders and corded.

The angle grinder are great for heavy-duty jobs like grinding down welds, removing rust, cutting metal, and smoothing out imperfections on machinery and metal parts.

Grinders have a sturdier construction and more torque compared to typical rotary tools used on wood and plastic. Safety gear like eye protection is important when using them.

Features

- Size: bigger and more powerful.

- Use: great for heavy-duty tasks in industrial settings.

- Power Source: They can be powered by air compressors or electricity.

- Applications: versatile use for grinding, cutting, polishing, and shaping materials.

- Pros:

- More powerful

- Can handle heavier-duty tasks

- More durable

- Less expensive

- Cons:

- Larger and heavier

- Less portable

- More dangerous

What is dremel

Dremel is the leading brand name of rotary tools. Dremel rotary tools operate at 5,000 to 35,000 rpm and are designed primarily for grinding, sanding, polishing, sharpening, engraving, carving, cutting and routing a wide variety of materials.

They have a pencil-grip body for precision handling and accept hundreds of different bit attachments and accessories.

Both corded and battery-powered cordless Dremel rotary tools are available. The Dremel name is synonymous with high-quality rotary tools.

- Size: Dremel tools are smaller and more compact.

- Use: They are perfect for detailed and precision work.

- Power Source: They are powered by electricity.

- Applications: Dremels are great for tasks like engraving, carving, drilling, and sanding.

- Pros:

- Smaller and lighter

- More portable

- Easier to use in confined spaces

- Better suited for light-duty tasks

- Cons:

- Less powerful

- Not as durable

- More expensive

Die grinder vs rotary tool ( dremel tool )

Power Differences

The most noticeable difference between these rotary tools is sheer power and speed:

- Die grinders have 1 to 2 horsepower motors

- Dremels max out around 130 Watts, about 1/5 the power

The ability to sustain extremely high speeds and quickly remove material makes grinders suitable for tasks like:

- Cutting and grinding metals

- Removing stubborn bolts, rivets, and screws

- Chiseling out mortar from brick and concrete

Dremels lack the brute force necessary for these heavy duty jobs, but provide ample power for light grinding, polishing, cleaning, and engraving work.

Power sources

Both differ in their sources of power. Dremels are powered by electricity that is fed into the tools either through a power cord or a battery. In the cordless version, the tool dies when the battery runs low. Therefore, you need to either change the battery or recharge the tool in order to continue using it again.

Die grinders are powered by an air compressor. This produces more power as the tools require more energy to run. The air compressors are refilled by either replacing the cylinders or using compressor machines.

Sizes

One of the reasons why people like Dremel rotary tool is that it comes in a small compact size. This makes it one of the most portable and agile power tools on the market. You can therefore use this device for long hours without feeling fatigued.

Die grinders on the other hand comes in much larger sizes. This means that they will not only be a bit bulkier to carry, but also quite heavier. The large size is as a result of bigger features such as an air compressor and others. However, these features make for a more powerful tool that can handle heavy duty projects.

Precision and Control

Dremels have the edge when it comes to precision work and control:

- Lower speeds allow for more controlled, safer operation

- Compact size and pencil-like grip enhances maneuverability

- Range of engraving, carving, and cleaning attachments cater to detail work

Conversely, die grinders are made for rapid stock removal not delicate precision work. Their larger size makes them harder to manipulate for intricate jobs. Excessive vibration at max RPMs also hinders fine work.

Speed of the tools

Dremel are some of the fastest rotary tools on the market. This is because they come with a speed of about 35000 rpm. This speed is applicable on both corded and cordless rotary tools on the market. Dremel comes variable speed setting system to regulate the speed.

Grinders rotate at a speed of between 20,000 and 25000 rpm. This is dependent on the task that you want to handle as well as the type of bit that you are using. However, the tool comes with a speed adjustment system that can enable you to choose a speed that suits the job that you want to do.

Cost Considerations

Dremels are the more affordable option for the average DIYer:

- Basic models start at $50

- Die grinders start around $100 and increase in price significantly for higher power models

The lower cost of Dremels reflects their less demanding design requirements compared to professional-grade die grinders.

Heat removal properties

Dremels use an electrical motor that generates heat especially when run for long periods of time. This can bring an inconvenience to the user since they have to stop working in order to allow the device to cool down.

Die grinders are better placed to handle heat because they operate on an air compressor. As a result, you can use them for many hours without getting affected by heat.

Safety Precautions

Operating any power tool requires proper safety precautions, but die grinders pose heightened risks:

- High speeds increase chances of cutting and abrasion injuries

- Powerful torque can twist or sprain wrist if wheel binds

- Potential for wheel disintegration with improper wheels at high RPM

- Eye protection, face shield, ear protection highly recommended

Dremels run at slower speeds and lower power, reducing risks. But eye protection and care is still a must when using a Dremel.

Safety Precautions

Operating any power tool requires proper safety precautions, but die grinders pose heightened risks:

- High speeds increase chances of cutting and abrasion injuries

- Powerful torque can twist or sprain wrist if wheel binds

- Potential for wheel disintegration with improper wheels at high RPM

- Eye protection, face shield, ear protection highly recommended

Dremels run at slower speeds and lower power, reducing risks. But eye protection and care is still a must when using a Dremel.

Which Tool is Right for You ?

The best tool for you will depend on the specific tasks you need to complete. If you need a powerful tool for heavy-duty work, a die grinder is the better option. If you need a smaller, more portable tool for light-duty work, a Dremel is the better choice.

Conclusion

Dremel vs die grinder are important in any workshop. However die grinders are suitable for heavy duty tasks than the Dremels. Consider the task at hand, your budget, and the level of control you require to make the right choice between a Dremel and a die grinder.

Refence: https://besttoolreview.net/die-grinder-vs-dremel/

FAQ’s

Yes, you can use die grinder for cutting various materials such as metal, plastic, and wood. Its important to always follow safety guidelines to ensure proper and safe operation.

Some popular brands are Dremel, Ryobi, and Bosch. They offer a wide range of accessories, attachments, and options as per user preferences.

Die grinders common use is metalworking but they can also be use for wood with suitable attachments. Use the right tool and proper safety precautions when working with different materials.

Angle grinders and die grinders have some similarities but both are design for different jobs. An angle grinder primarily use is cutting and grinding large areas, while a die grinder is suitable for intricate tasks.

Yes, you can use a die grinder as a Dremel. Both can be use for various tasks such as grinding, cutting, carving, and etching.