Shaper vs Router: Understanding the Differences and Uses

Woodworking, an age-old craft, has evolved significantly with the advent of modern tools, enhancing both precision and efficiency. At the heart of this evolution are tools like the wood router and the shaper, each boasting distinct features and capabilities. While both are instrumental in shaping and molding wood, their applications and functionalities differ considerably.

A table highlighting their key differences a shaper and a router:

| Feature | Wood Router | Shaper |

|---|---|---|

| Size | Generally compact and portable | Larger, stationary |

| Power | Suitable for light to medium tasks | Designed for heavy-duty tasks |

| Versatility | High with various bits available | Specific cutters for set tasks |

| Cost | Typically more affordable | Pricier due to robust build |

Choosing between these tools isn’t merely about preference; it’s about understanding the demands of the task at hand and selecting the tool that aligns best with those needs. Making the right choice can be the difference between a flawless finish and a botched job.

What is a Wood Router?

A wood router, a cornerstone in the realm of woodworking, is a versatile machine designed primarily for hollowing out or creating intricate patterns on wood. Its precision cutting capabilities, often determined by the RPM of the spindle, have made it a favorite among craftsmen, especially for detail work. The collet of the router holds the bit securely, ensuring consistent performance. Many professionals also use a router table to enhance stability and precision, especially for certain tasks that require a stationary setup. Its precision cutting capabilities are often powered by universal motors, which offer variable speed controls to adjust the RPM based on the task. Proper dust collection is essential when using a router to maintain a clean workspace and prolong the tool’s lifespan.

Common Use

- Edge Profiling: Giving a decorative finish to the edges of wood.

- Dadoing: Creating a slot or trench in wood work project, especially in cabinetry.

- Rabbeting: Carving a recess along the edge of a wood piece.

- Pattern Cutting: Using templates to create identical shapes and designs.

Types of Wood Routers

- Handheld Router: Portable and ideal for light tasks.

- Plunge Router: Allows the bit to be plunged into a wood piece, suitable for interior cuts.

- Fixed Base Router: Offers more stability, especially for edge cuts and molding.

Notes:

- The versatility of the wood router is enhanced by the wide range of router bits available, each designed for specific tasks. You Check Best Router Bits Guide.

- Speed control is crucial when using different bits to ensure the best finish and prolong the life of the tool.

What is a Shaper?

A shaper, often considered the heavyweight in wood shaping, is a stationary machine designed for larger, more intensive woodworking projects. Unlike routers that typically use universal motors, shapers often employ induction motors for consistent power and durability. Its robust build and power feeder ensure that wood is fed consistently for precise cuts. Unlike the router, the shaper can often handle tasks in one pass due to its power. They excel in tasks like planing and creating detailed moldings in just one pass.

How It Differs from a Wood Router

- Power & Capacity: Shapers are built for continuous use and can handle thicker and harder wood with ease.

- Cutters: Unlike routers that use bits, shapers use cutters, which are larger and designed for specific shapes.

Common Use

- Molding: Creating detailed and decorative moldings.

- Tenoning: Crafting tenons for joints.

- Edge Treatments: Similar to routers but on a larger scale.

Table: Shaper Cutters and Their Uses

| Cutter Type | Use |

|---|---|

| Straight | For straight cuts and grooves |

| Raised Panel | Crafting raised panels for doors |

| Stile and Rail | For frame pieces in door construction |

Notes:

- Shapers are typically used in professional workshops due to their size and cost.

- They offer craftsmanship that’s hard to achieve with other tools, especially for large-scale projects.

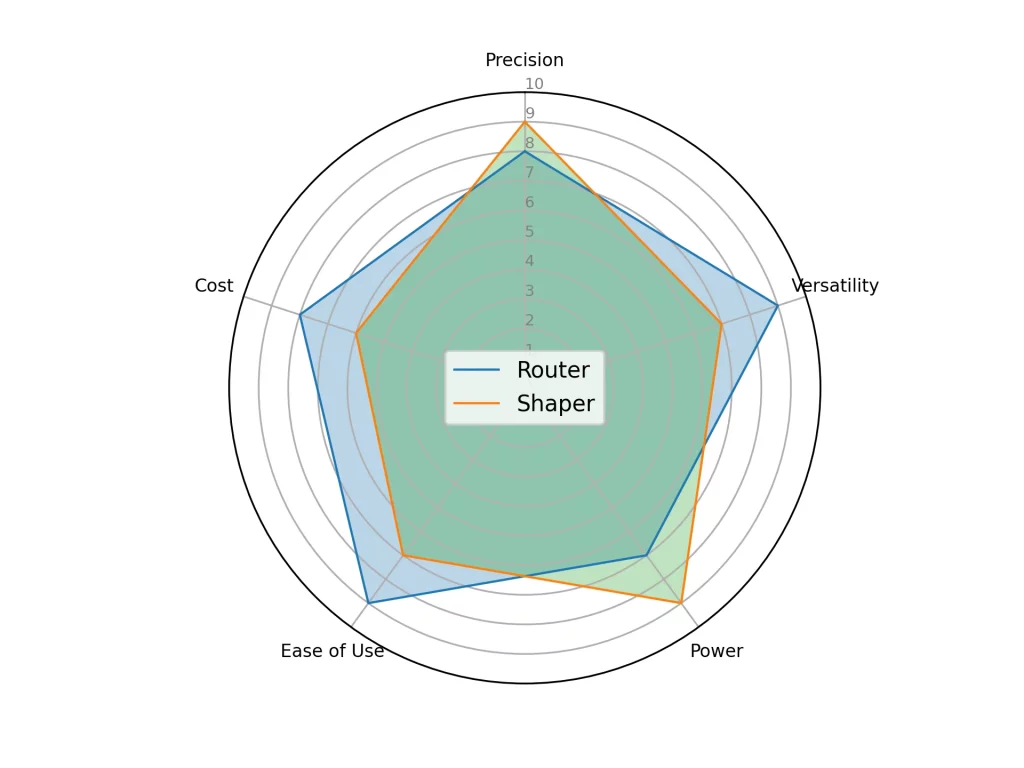

Key Differences Between Shaper and Router

Size and Physical Structure

- Wood Router: Compact and designed for portability, wood routers are often handheld, allowing for maneuverability and ease of use in various positions.

- Shaper: Stationary and robust, shapers are built to stay in one place, typically on a workbench or stand, and handle larger pieces of wood.

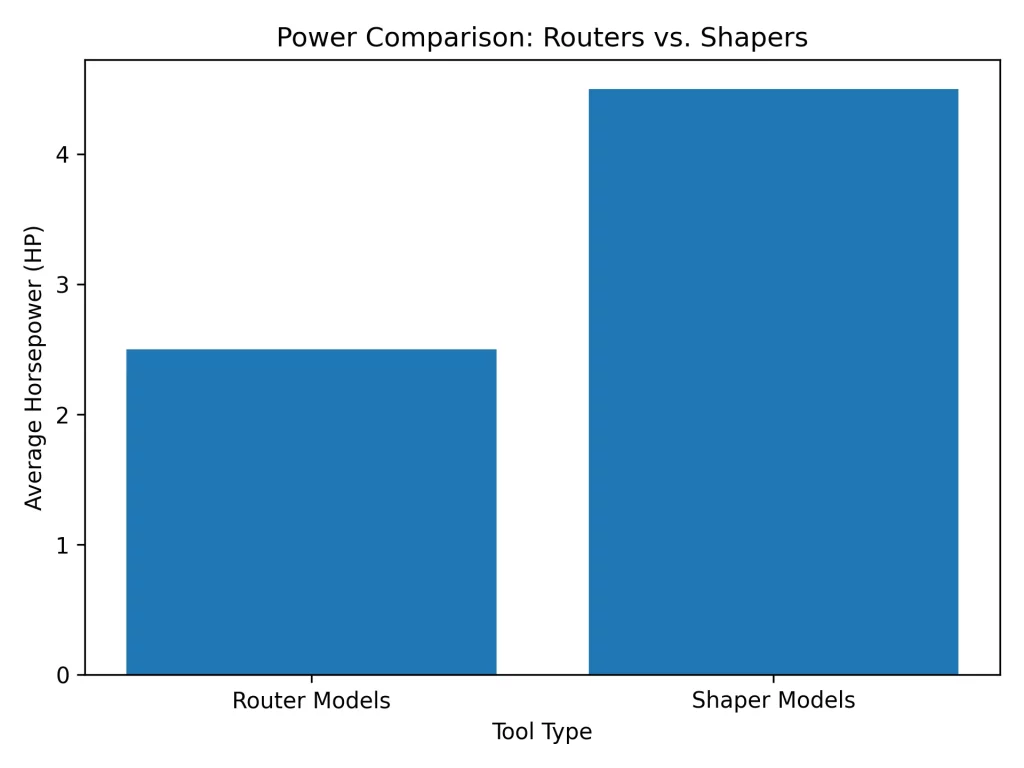

Power and Capacity

- Wood Router: Suitable for light to medium tasks, routers typically have a variable RPM allowing for adjustments based on the task. They might require multiple passes for thicker wood. Their motor power usually ranges from 1 to 3 HP. They are perfect for hobbyists and DIY enthusiasts.

- Shaper: Built for heavy-duty tasks, shapers come with a more potent motor and can often achieve the desired shape in one pass. The power feeder ensures consistent feeding of wood. Its power full 3 HP and above motor making them ideal for professional wood workers .

Versatility and Types of Jobs

- Wood Router: Known for its versatility, the router, with its variety of bits, can handle a wide range of tasks from edge profiling to intricate pattern designs.

- Shaper: While not as versatile as routers, shapers excel in specific tasks like molding, tenoning, and other heavy-duty applications.

Table: Bit and Cutter Types for Routers and Shapers

| Tool Type | Bit/Cutter Name | Primary Use |

|---|---|---|

| Router | ||

| Straight Bit | For making straight cuts in wood. | |

| Rabbeting Bit | Used to create a shoulder or step cut along the edge of a workpiece. | |

| Chamfer Bit | For making beveled or angled cuts. | |

| Edge Forming Bit | Used for creating decorative edges on wood. | |

| Flush Trim Bit | For trimming the edge of one material flush with the edge of another. | |

| Cove Bit | Used to cut a concave quarter-circle profile into the edge of a workpiece. | |

| Dovetail Bit | For creating dovetail joints in woodworking. | |

| Shaper | ||

| Straight Cutter | For making straight cuts and grooves. | |

| Raised Panel Cutter | Used for crafting raised panels, typically for doors. | |

| Stile and Rail Cutter | For creating frame pieces in door construction. | |

| Profile Cutter | Used for creating various profiles on the edge or face of a workpiece. | |

| Helical Cutter | For smoother cuts, especially on difficult grain patterns. | |

| Molding Cutter | For creating various molding profiles. |

Cost Considerations

- Wood Router: Generally more affordable, making it a popular choice for beginners and those on a budget.

- Shaper: Given its build quality, power, and precision, shapers are pricier but are seen as a long-term investment, especially for serious woodworkers.

Table: Quick Comparison Between Router and Shaper

| Feature | Wood Router | Shaper |

|---|---|---|

| Size | Compact, Portable | Large, Stationary |

| Power | 1-3 HP | 3 HP and above |

| Versatility | High versatility with various bits | Specific tasks with cutters |

| Cost | More affordable | Pricier, long-term investment |

Notes:

- The choice between a router and shaper often boils down to the specific requirements of the project and the frequency of use.

- Both tools, while having overlapping functionalities, have distinct advantages that cater to different woodworking needs.

Advantages of Using a Wood Router

Precision and Detail Work

- With its compact design and a plethora of available bits, the wood router excels in delivering intricate designs and patterns, making it a favorite for detail-oriented tasks.

Portability and Ease of Use

- Being lightweight and handheld, wood routers can be easily transported and used in various locations, offering flexibility to woodworkers.

Wide Range of Available Bits

- From straight bits to dovetail bits, the variety allows woodworkers to achieve a multitude of finishes and designs.

Notes:

- The wood router’s versatility makes it a staple in both professional workshops and home garages.

- Proper maintenance and bit selection can significantly enhance the router’s performance and lifespan.

Advantages of Using a Shaper

Handling Larger Projects

- With its robust build and powerful motor, shapers can manage bigger and more intensive woodworking projects with ease.

Durability and Stability

- Shapers are designed for continuous and heavy-duty use, ensuring longevity and consistent performance.

Advanced Shaping Capabilities

- The specific cutters designed for shapers allow for more advanced and precise shaping, especially for tasks like molding and tenoning.

Notes:

- While shapers might have a steeper learning curve compared to routers, mastering them can elevate the quality of woodworking projects.

- Investing in high-quality cutters and regular maintenance can optimize the shaper’s performance.

Making the Right Choice for Your Project

Assessing the Project Requirements

- Size and Scope: For smaller projects or detailed work, a wood router might be more suitable. In contrast, larger projects that require heavy-duty shaping would benefit from a shaper.

- Frequency of Use: For occasional woodworking tasks, investing in a router might be more cost-effective. However, for regular and intensive use, a shaper’s durability becomes an asset.

Considering the Tool’s Limitations

- Wood Router: While versatile, routers might struggle with very thick or hard wood. Their portability, while an advantage, can also lead to less stability during certain tasks. The choice of collet and bit can influence the router’s performance.

- Shaper: Shapers, being stationary, lack the flexibility of routers. They also require a more significant initial investment and might be overkill for simple tasks. The difference between a shaper and a router often boils down to the intensity and scale of the task.

Cost-benefit Analysis

- Initial Investment: Routers are generally more affordable, making them a popular choice for beginners. Shapers, while pricier, are seen as a long-term investment for serious woodworkers.

- Operational Costs: Consider the cost of bits for routers and cutters for shapers. While router bits are more affordable, shaper cutters, being more durable, might offer better value over time.

Table: Decision Factors Between Shaper vs Router

| Factor | Wood Router | Shaper |

|---|---|---|

| Project Size | Best for small to medium projects | Ideal for larger projects |

| Flexibility | High flexibility and portability | Stationary, specific tasks |

| Cost | Lower initial cost | Higher initial, long-term value |

Notes:

- It’s essential to consider both current and future woodworking goals when deciding between a router and shaper.

- Both tools, while having their unique strengths, can coexist in a well-equipped workshop, complementing each other’s capabilities.

FAQs

Why would you use a shaper instead of a router?

- Shapers are designed for continuous, heavy-duty tasks. They excel in handling larger projects, especially when working with thicker or harder wood. Their stationary nature provides stability, ensuring precision in tasks like molding and tenoning.

Can a router do the same job as a shaper?

- To some extent, yes. Routers are incredibly versatile and can handle a wide range of tasks. However, for more intensive jobs or when working with larger wood pieces, a shaper’s power and durability become essential.

Which is more versatile: a router or a shaper?

- A router is generally more versatile due to its portability and the variety of bits available. It can be used for a broader range of tasks, from edge profiling to intricate pattern designs. Shapers, while not as flexible, excel in specific, heavy-duty tasks.

How do I decide between buying a router or a shaper?

- Consider the nature and frequency of your woodworking tasks. For detailed work or occasional projects, a router might be more suitable. For regular, intensive tasks, especially on a professional scale, investing in a shaper could be more beneficial.

Conclusion

In the vast realm of woodworking, both the wood router and the shaper hold significant places, each boasting its unique strengths and applications. While the router offers unparalleled versatility, especially for intricate designs and detail work, the shaper stands out in its power and precision for larger, more intensive tasks.

The choice between the two isn’t black and white. It hinges on the specific requirements of the project, the frequency of use, and, of course, budget considerations. For hobbyists and DIY enthusiasts, the router’s flexibility might be more appealing. In contrast, professional woodworkers might lean towards the durability and advanced capabilities of the shaper.

In the end, understanding the nuances, advantages, and limitations of each tool is crucial. It’s not about which tool is better in a general sense, but which tool is right for the job at hand. And in a well-equipped workshop, these tools can coexist, complementing each other and elevating the quality of craftsmanship to new heights.

You can read more at