A Stitch In Time Saves Nine! The Intricacies Of Maintaining A Wood Router

A wood router is every wood worker’s prized possession, a baby we say at the cost of sounding outrageous!

We know how much time you have spent…

…let alone working on one but also in selecting one!

So I am sure you would be concerned about the router giving you your money and time’s worth. A few minutes of regular maintenance, every week or so, can do wonders in increasing the longevity of your router and its parts.

How frequent the maintenance will be required will depend on the type of wood you work on (resinous woods like pine, leave residue and hence require more attention); and the intensity-duration of your work.

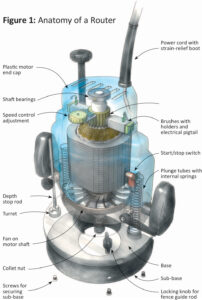

When we say a router needs maintenance it means all the components and accessories will need checking and repairs/replacement.

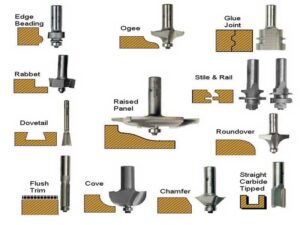

Bits –

This is the part that is always in action and hence needs the most attention! With continuous use, the carbide edges of the bit start gathering pitch, grime and dirt. With such a build up, the bit will get heated up while working and slowly lose its sharpness.

Clean the bit regularly with a brass brush, cleaning solution and sharpen the edges. Sharpen only the flat side with a honing file or if you are not sure how to sharpen properly get it done professionally. If the bit has a removable pilot bearing then take it off.

Dust accumulation will not let the bearing rotate freely and leave burn marks on the wood. Scrub the dirt/pitch with a brush and you could also give the bearing a solvent bath.

Make sure to dry it completely and then apply light oil for lubrication. If the bearing is beyond repair, replace it. Also take care to store your bits properly; composite bit holders are available in the market.

Collet & Shaft –

It, being the point of contact between the router and bit, needs careful inspection. Dust, corrosion or dirt will decrease the ability of the collet to grip or release the cutter shank.

Such built up there will cause the bit to slip or get stuck. Give the collet and retaining nut a solvent bath. Keeping the inside of the collet nut clean and free of any burrs is essential to prevent cross threading and damage to its threads. Clean the inside of the end of the shaft with a brush.

Air Vents –

With the help of a vacuum cleaner, clear out any debris at the top and bottom vents of the router. If the dirt is concentrated and stubborn use a blowing gun to clear it.

Brushes –

If you observe excessive sparking from the motor area of your router and its power has reduced then the brushes are the culprits. They need to be changed.

Base –

Having the base of the router waxed will ensure even and smooth movement of the router over the wood.

A router works hard, take care of it! Keep it enclosed, in a dry place. Don’t forget to unplug the router before performing any maintenance!